Effective Handover of Projects to Operations Teams

This article focuses on project handover of large scale, complex industrial projects to operations teams. However, the complexity and number of activities and deliverables are huge and cannot be covered in detail in an article of this nature.

Introduction

Project handover is a process of transition, not a date, and should not only be initiated once a project is completed or approaching completion.

This article focuses on project handover of large scale, complex industrial projects to operations teams. However, the complexity and number of activities and deliverables are huge and cannot be covered in detail in an article of this nature.

The different role players are described, as well as their focus during project execution and implementation, related to effective project handover to operations teams. A summary of potential deliverables is presented at the end of the article.

Project handover

The APM Body of Knowledge (APM, 2012) defines handover as “the point in the life-cycle where deliverables are handed over to the sponsor and users”. Anthony (2017) suggests that there are many scheduled ‘mini handovers’ as the project progresses such that at the end of handover, all project assets, -information and -data have been transferred to the owner. An effective handover will enable the owner to operate, maintain and support the plant through its lifetime in a safe and responsible manner. Here ‘effective’ means successful in producing a desired or intended result.

Owner representatives should get involved on the project team timeously. The different role players of the project should all understand their responsibilities to achieve handover and be aligned on what deliverables will be transferred.

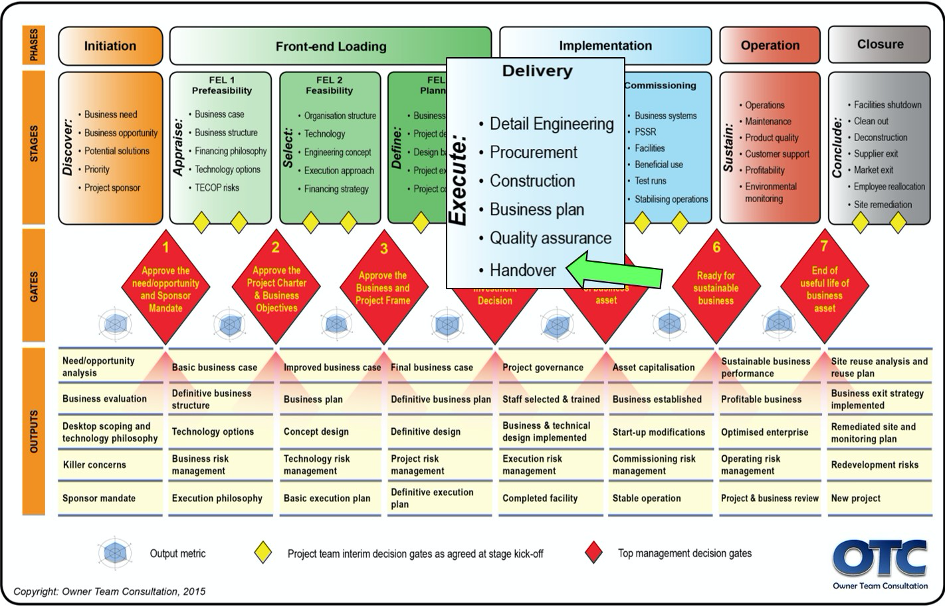

There are many models illustrating the different phases of project execution. The OTC Stage-Gate Model which covers the life-cycle of a project, describes the outputs to be delivered at the end of each stage of a project. Handover is a specific deliverable of the Delivery Stage, prior to plant commissioning, as highlighted in Figure 1.

Figure 1: OTC Stage-Gate Model, highlighting ‘handover’

Roles and responsibilities of the different teams

Owner project team

The owner develops the business objectives and specifications of a new product and facility to satisfy business needs. During project execution, the owner must ensure that quality of engineering work, procurement, manufacturing and construction meet the required specification. We recommend that the owner appoints an Owner Project Management Team (Owner PMT) to manage this process and to represent the owner, as shown in Figure 2.

The Owner PMT is represented by the triangle, the project manager as the leader and accountable person, supported by a business-, operations- and engineering manager and their respective teams. The suppliers, contractors and other service providers (executing the project) are managed by the Owner PMT.

It is the responsibility of the Owner PMT to obtain owner acceptance of the project at handover and should work towards achieving it, as the project proceeds through the different stages. Project deliverables, required at handover to enable operations teams to take custody of assets and to operate and maintain it in a sustainable way, are covered later in the article.

Figure 2: Owner PMT (van Heerden, Steyn & van der Walt, 2015)

The project team must ensure completeness of deliverables at handover and should focus on the following aspects:

- Review, before the commencement of a new project, the knowledge, experience and lessons, learned from previous projects;

- Agree upfront upon deliverables, required at handover, i.e., what, when, format and method of transfer. End-of-job documentation needs to be meaningful and coherent to the owner;

- Review documentation continuously (according to schedule, including sample checking and feedback on issues) and obtain owner’s acceptance;

- Ensure the on-boarding of sufficient owner representatives who are both empowered and competent;

- Ensure competent role players are engaged at the right time and retained for the project duration;

- Ensure the owner understands and is prepared organisationally and operationally to support handover and to execute commissioning and operation of facilities;

- Arrange post-handover, on-site support from the project team, to implement start-up modifications, if required; and

- Ensure compliance of deliverables to agreed requirements.

Business and operations teams

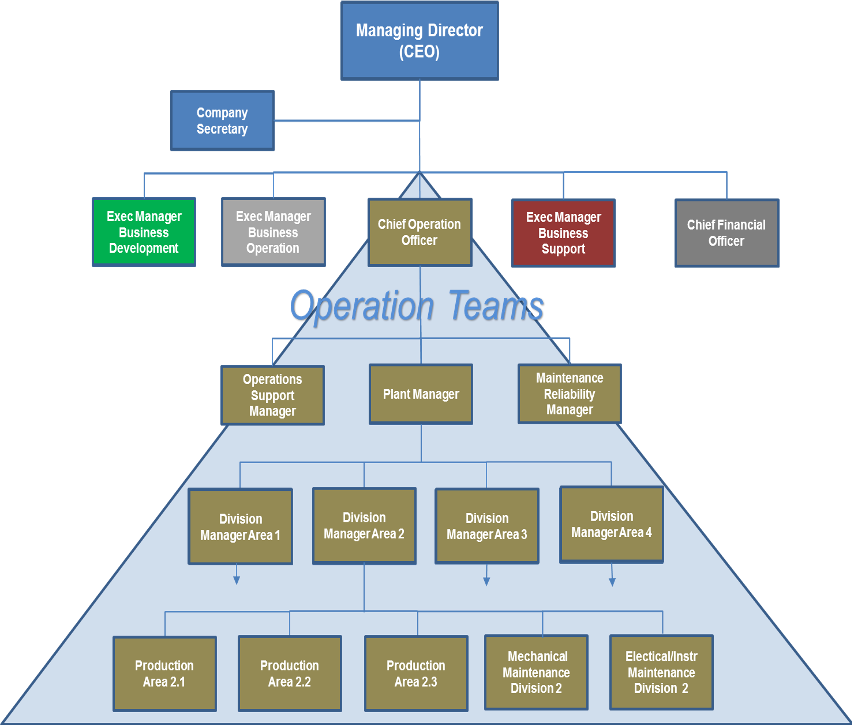

The organisation structure of a typical operational business is depicted in Figure 3. The figure shows several executive managers, including the chief operating officer (COO), reporting to the managing director or CEO. Most of the personnel in the organisation will report indirectly to the COO position and are referred to as operations teams in this article. Direct reports to the COO position include:

- Operations support manager: Responsibilities include safety, health, environmental, risk and quality management, laboratory and technical (all engineering disciplines);

- Plant manager(s): Responsible for production divisions (four are shown in Figure 3), each comprising production and maintenance teams. Large organisations may have several operating facilities and consequently several plant managers; and

- Maintenance reliability manager: Responsibilities include inspection, maintenance planning, rigging and crane services, maintenance services, refurbishment, and specialised maintenance.

Figure 3. Typical business organisational structure, highlighting operations

Manufacturing businesses often describe their value chain as buy, make and sell. The make, or running part of the value chain, is about the management of sustainable operations. The COO is accountable for managing operations, supported by teams, referred to as operations teams, residing in operations support, maintenance reliability, production and maintenance (see Figure 3).

According to Govindsamy (2014), these operations teams are accountable to manage operations by focusing on the following core processes:

- Lead operations performance;

- Plan operations;

- Run operation and facilities;

- Protect and sustain the agreed baselines;

- Analyse and review operations;

- Evaluate technical capabilities of operations;

- Optimise the operations;

- Mobilise operations knowledge; and

- Mobilise people capacity.

When new projects impact an operations area, production, maintenance and engineering representatives must be seconded from there to the Owner PMT. Operations team members in the Owner PMT must ensure that project deliverables, required at handover to establish and execute above-mentioned processes, are defined during the front-end loading phase of the project and assure compliance thereof up to and at project handover.

Project deliverables at handover

The cutting of a ribbon at a glamorous ceremony often symbolises the completion and handover of a project. Before the owner cuts the ribbon, end-of-job documentation is one of the most important deliverables, required by the owner at handover. End-of-job documentation provides insight in: the specifications of the facility, design, procurement and manufacturing of equipment, construction, hook up of different systems, training records of production and maintenance staff, and the certificate of completion of the facility, issued by the project manager.

As mentioned earlier, the owner needs to specify, and the project team provides deliverables (end-of-job documentation) according to an agreed schedule, enabling the owner to prepare for ownership (commissioning, production, maintenance, optimisation, eventual shutdown and site remediation) of the facilities after handover.

The magnitude and complexity of end-of-job documentation makes it impossible to compile a complete list in an article like this. However, a few of the essential documents are listed below (adapted from McIntosh, 2017):

Process engineering documentation & drawings:

- Design basis, including process descriptions, feed consumption and yield, control philosophy, plant availability, material and energy balances and simulation models;

- Operating manuals, covering safe-making procedures and various types of start-up, run and shutdown scenarios;

- Trouble-shooting manual;

- Training manuals;

- Training records;

- Drawing index;

- List of cancelled drawings;

- Block flow diagrams;

- Process flow diagrams; and

- Process & instrumentation diagrams.

Other engineering disciplines’ documentation & drawings:

- Design philosophy, basis, standards and specifications;

- Design calculations;

- Equipment data sheets;

- Test reports;

- Certificates of compliance;

- Code data books of vessels (mechanical);

- Signed-off punch lists;

- Register of approved specification concessions;

- Certificate of completion of subsystems;

- Transfer of care, custody, and control documents of sub-units;

- Maintenance manuals, procedures and schedules;

- Training manuals and training records; and

- Discipline related engineering drawings.

Safety file:

- Health impact assessment;

- Safe work instructions;

- Hazardous Substance Risk Assessment;

- Material Safety Data Sheets;

- Flare systems;

- HAZOP study minutes and reports;

- Firefighting equipment; and

- Gas detection systems.

Environmental file:

- Strategic environmental assessment (if done);

- Environmental impact assessment;

- Environmental management plan;

- Environmental permits; and

- Reporting requirements.

Closing remarks

Effective project handover is a win-win outcome. The project team is recognised by the owner for creating a facility that meets owner requirements by accepting handover, while the owner is assured that the facility can be operated, maintained and improved in a sustainable way.

References

APM (Association for Project Management), 2012, APM Body of knowledge, 6th edition, Association for Project Management, Princes Risborough, UK.

Anthony, O., 2017, APM Research Fund Series: How can we hand over projects better. Available fromhttps://www.apm.org.uk/media/6153/handoverreport_2017_final.pdf, Accessed on 21 April 2018.

Govindsamy, N., 2014, A critical review of Operations Excellence programs: A petrochemical company as case study. Available from http://dspace.nwu.ac.za/bitstream/handle/10394/11551/govindsamy_n.pdf;jsessionid=016661DAE956D25B37F0B11A5FCCB061?sequence=1, Accessed on 21 April 2018.

McIntosh, S.A., 2017, The importance of project handover documentation. Available from http://www.long-intl.com/articles/Long_Intl_The_Importance_of_Proj_Handover_Docs.pdf, Accessed on 23 April 2018.

van Heerden, F.J., Steyn, J.W. & van der Walt, D., 2015, Programme management for owner teams- a practical guide to what you need to know, OTC Publications, Vaalpark, RSA.

Corne Thirion

Consulting Partner

Cornè is a graduate electrical engineer with a Certificate of Competency from the RSA Department of Manpower. His career of over 38 years started in the steel industry before he moved on to the petrochemical industry. More...

DOWNLOAD

You might also enjoy:

Technology Innovations to Improve Industrial Health & Safety

Are serious accidents inevitable in heavy industry? Why, despite our best efforts, do fatalities continue to occur? Can technology play a role in improving safety performance? Are there any emerging technologies that could result in a breakthrough improvement in health and safety performance in industries such as mining, oil & gas, chemical, and others?

Learning from All Projects

Any organisation should strive for continual improvement in the way they execute projects. A good way to do this is to ensure that mistakes of the past are not repeated.

Smart Factories and the ‘New Normal’

It was only a short 12 months ago that things were vastly different. At the time, I wrote an article entitled Beyond Capex: Future-proofing your IT investment for sustainable value delivery (Halse, 2019). The article introduced smart manufacturing and covered the...