An Introduction to Project Logistics Management

Most people in the project and business environment are familiar with the terms ‘logistics management’ and ‘supply chain management’, until they’re asked to explain the difference. In this article, we discuss these terms and then focus on the unique aspects of ‘project logistics’.

Introduction

Consider the situation: your project, in some faraway location, is partly completed, but you urgently need 20 12” high-pressure valves to proceed. This is not an item stocked by local suppliers, if indeed there are any suppliers in the area. Sourcing the items from your preferred supplier will take at least two weeks.

Now, if the installation of these valves is not on the critical path for the project, it should not result in schedule slippage. The required items can be sourced and delivered in time, albeit at a cost premium. If it is on the critical path, you stand to delay completion by two weeks. This is something any respected project manager would want to avoid.

Is there anything worse, not considering accidents and manpower problems, than not having the specific items required for your project at the right place, at the right time and in the right quantities? We can think of several:

- The items are available in the project store, but nobody knows it’s there;

- Items not meeting the required specification;

- The items were mistakenly used for another application; and

- The items were deliberately used for another application.

These are all matters relating to logistics, in general, and project logistics, in particular.

Project logistics in perspective

Most people in the project and business environment are familiar with the terms ‘logistics management’ and ‘supply chain management’, until they’re asked to explain the difference. In this article, we discuss these terms and then focus on the unique aspects of ‘project logistics’. Another frequently used term in the building industry is ‘construction logistics’, but we’ll explain why we steer away from using it for projects in the process industries.

The Council of Supply Chain Management Professionals (CSCMP, 2016) defines logistics management is that part of supply chain management that plans, implements, and controls the efficient forward and reverses flow and storage of goods, services and related information between the point of origin and the point of consumption to meet customers’ requirements.

Supply chain management encompasses the planning and management of all activities involved in sourcing and procurement, conversion, and all logistics management activities (CSCMP, 2016). It also includes coordination and collaboration with supply chain partners, namely suppliers, intermediaries, third-party service providers, and customers. Supply chain management effectively integrates supply and demand management within and across companies.

From the two definitions, we see that logistics management is a subset of supply chain management. Considering the discipline of project management for a moment, we see that this overlaps onto supply chain management, insofar as construction of a new facility is concerned: materials and services need to be available when needed by the construction crew. This is illustrated in Figure 1, where the overlap gives rise to the terms ‘project supply chain management’ and ‘project logistics management’. Project logistics is a subset of logistics and project supply chain management a subset of supply chain management.

Figure 1: Project logistics in perspective

This begs the question: is project logistics then just simplified logistics? The answer is ‘yes’, in the sense that there is only inbound logistics, with perhaps some reverse logistics to return faulty equipment. However, every project is unique and every project site is different. This effectively means that for every project, every supply chain is new and has not had the benefit of supply chain optimisation and fine-tuning. In this sense, the answer to the question is a resounding ‘no’.

New process facilities can consist of hundreds of thousands of individual components. Each should be available at the right location, the right time, the right quality and at the right price.

Characteristics of project logistics

Projects logistics already commences in the feasibility study stage of a project. Accessibility to the site, in terms of transport routes, rail carrying capacities and bridge widths, can dictate the design approach to be followed. In the situation where very long lead-times for equipment apply, it may have to be ordered before completion of the final design. It is this early involvement of supply chain professionals in a project which guides us away from the term ‘construction logistics’ and is why we rather use ‘project logistics’.

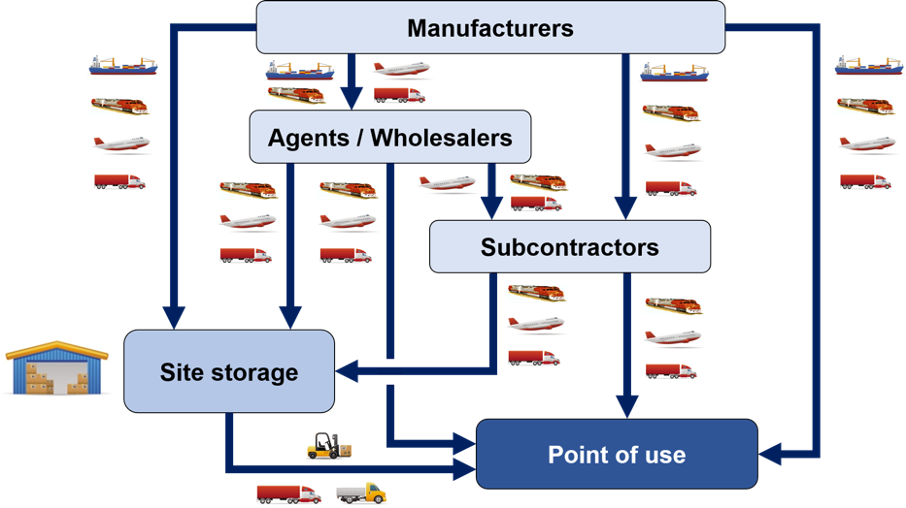

The different component delivery channels for a typical large process facility is shown in Figure 2. Some of the transport options are also shown in the graphics. Considering the large number of components for a given project, the complexity of project logistics can be appreciated.

Figure 2: Component delivery channels

The project supply chain is characterised by the following elements, which differentiate it from supply chains for manufacturing and retailing:

- Converging: All materials converges on the construction site where the facility is assembled from incoming materials. The construction effort is directed to a single product, namely the processing facility;

- Temporary: Apart from rare exceptions, a project supply chain is temporary, producing one-off construction projects through repeated reconfiguration of project contractors and suppliers; and

- Made-to-order: Projects require made-to-order supply chains, with every project creating a new facility. There is little repetition, again with minor exceptions.

What is required for a process plant?

We’ve already mentioned the large number of materials, components, equipment and services that are required for the construction of a process plant. In this section, we briefly describe the different categories of materials and equipment.

An overview of the materials, components and equipment for a process plant is given in Figure 3.

Figure 3: Materials, components and equipment for a process plant

We categorise the materials, components and equipment as follows:

- Bulks: Bulk and generic materials, requiring basic specifications, no pre-delivery checking and limited quality control. Examples include basic building materials like sand, stone, wood, cement and bricks. We group common safety equipment like hard hats, safety boots and safety gloves in this category;

- Commodities: Generic equipment, bought to specification following a visit to the suppliers site and requiring active quality control. Examples include structural steel, pipes and pipe fittings, valves, small pumps, cabling, field instruments, etc.;

- Process equipment: This category covers process equipment requiring detailed specifications, astute vendor selection, site visits and quality control. Examples include process vessels, tanks, heat exchangers, columns, and process control equipment;

- Modular plant units: Modular plant units are prefabricated process units designed, built, tested and then delivered to site. Plant modules could be anything from basic pre-assembled pipe-racks (PARs) to third generation plug-and-play modules;

- One-off high-value items: One-off high-value items are typically large high-value and long-lead items built to very strict specifications with continuous quality assurance. Examples include large distillation units, unique process reactors and custom compressors and turbines; and

- Construction equipment: Heavy equipment to be used for the construction phase of the project, including cranes, graders, loaders, excavators, forklifts, bull dozers and trucks. Also includes the hand tools used by the construction artisan.

Logistics outsourcing

To become more cost effective and efficient, project managers and managing contractors have started to outsource project logistics. Outsourcing is the transfer of a function previously performed in-house to an outside service provider. Outsourced providers are often referred to as contractors or ‘third parties’. When work is outsourced, the outsourcing business or agency still provides oversight.

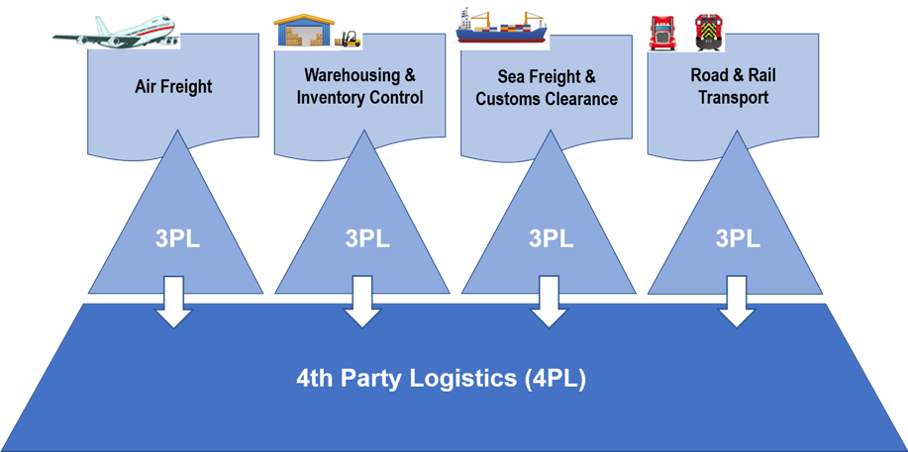

The concept of third-party logistics, or 3PL, appeared on the scene in the 1970s as the way to reduce costs and improve services. In the project environment, 3PL service providers would handle tasks ranging from trucking, marine cargo transport and specialist transport of very heavy loads, to broader activities serving the total project supply chain, such as inventory management and order processing.

In the past, many 3PL providers didn’t have adequate expertise to operate in complex and one-off supply chain structure such as is required for the construction of a large process facility. The result was the inception of another concept, namely fourth-party logistics or 4PL. Fourth-party logistics refers to a party who works on behalf of the client, typically the managing contractor responsible for engineering, procurement and construction (EPC), to do contract negotiations and management of performance of 3PL providers.

This concept is illustrated in Figure 4, where four different 3PL service providers are shown, each with his area of specialisation. These four 3PL service providers report to a coordinating 4PL service provider. As said above, the 4PL service provider reports to the project managing contractor, who is accountable to the business owner.

Figure 4: Third- and fourth-party logistics (Adapted from Benjabutr, undated)

Is this the full story?

To give a very short answer: “no”. The longer answer follows below.

The concept of logistics can be traced back to the wars of the Greek and Roman empires, when specific military officers were assigned the duties of providing services related to supply and distribution of troops and other resources.

During World War II, logistics evolved greatly. The United States military ensured that the required personnel, services and supplies were provided at the right time and at the right place. In their efforts to provide these services in the most optimal and economical manner, best practices to do the tasks were developed.

In the light of this little history lesson, the making available of qualified and experienced artisans and engineers at the project site is a crucial logistical issue. This is especially true if the chosen project site is far away from developed areas. Depending on the assignment of responsibilities in the project team, the project logistics manager may also be tasked with the provision of the workforce and other site infrastructure. These matters, critical to project success, which also require the benefit of project logistics management, include:

- Personnel supply: The right mix of engineers, welders, electricians, safety officers, clerks and labourers as may be required for the project;

- Personnel transport: Transport is required to get the personnel to their places of work and for personnel movement as the work dictates;

- Housing: Adequate housing for the personnel on or near the project site. In some cases, the erection of the required housing is the first part of a project;

- Canteen facilities: The personnel must be provided with nutritious and tasty meals three times a day to keep up their strength;

- Computing infrastructure: No project can proceed without an integrated business management system in place for the project execution phase

- Communication infrastructure: Intra-site communication, as well as facilities to allow site workers to communicate with their loved ones;

- Medical support: This is especially needed for undeveloped areas. Emergency medical treatment is required as a minimum, with arrangements in place for evacuation to a medical centre;

- Psychological support: Project work is a high-pressure environment and arrangements must be in place for psychological support for work or personal problems

- Waste management: Much waste is generated during the construction of any facility. Waste, especially hazardous waste needs to be disposed of responsibly, even if this means the construction of a dedicated hazardous waste disposal site.

Concluding remarks

Project logistics is a very complex field and covers a great many aspects. Apart from making sure that the hundreds of thousands of different items are available when required, the responsibilities of the project logistics manager can also include the supply and well-being of the construction team. We believe that this introduction to project logistics management will give the reader some appreciation of the complexity.

Outsourcing project logistics to third- and fourth-party logistics service providers (3PL and 4PL) can help the owner organisation and the EPC contractor achieve cost reductions and improves the probability of a successful project. Both the owner and the EPC contractor can learn from the project logistics service providers, because of the exposure to the best available project logistics practices and techniques.

There are several very useful books on construction and project logistics (Pryke, 2009; Sullivan, Barthorpe & Robbins, 2010; Lundesjö, 2015). Those who wish to learn more about supply chain management and logistics in projects are advised to read one, or more, of these.

References

Benjabutr, B., Undated, What is logistics and supply chain management? Available from http://www.supplychainopz.com/2012/04/what-is-logistics-and-supply-chain-management.html Accessed on 8 February 2017.

CSCMP (Council for Supply Chain Management Professionals), 2016, CSCMP Supply chain management terms and glossary. Available from http://cscmp.org/imis0/CSCMP/Educate/SCM_Definitions_and_Glossary_of_Terms/CSCMP/Educate/SCM_Definitions_and_Glossary_of_Terms.aspx?hkey=60879588-f65f-4ab5-8c4b-6878815ef921 Accessed on 4 April 2017.

Lundesjö, G. (ed), 2015, Supply chain management and logistics in construction: delivering tomorrow’s built environment. Kogan Page Limited, London.

Pryke, S. (ed), 2009, Construction supply chain management. Wiley-Blackwell, London.

Sullivan, G., Barthorpe, S. & Robbins, S., 2010, Managing construction logistics. Wiley-Blackwell, London.

Jurie Steyn

Consulting Partner, Director

Jurie holds a BEng(Chem)Hons and an MBA. He has more than 37 years of engineering, operations management and functional management experience. He started, developed and managed the Environmental & Risk Engineering group in Sasol Technology for more than 14 years. More...

Dirk Lourens

Consulting Partner

Dirk, a graduate mechanical engineer, is an experienced owner programme manager with a passion for results. He has over 40 years’ experience in general, technical and programme and project management with extensive global exposure.

DOWNLOAD

You might also enjoy:

Introduction to Constructability and Constuctability Programmes

This article focuses on the benefits of constructability, and implementation of a constructability programme in companies, at both corporate and project level Introduction Constructability is a project management technique for reviewing the whole construction process...

Strategic Corporate Social Responsibility for Projects

In this article, an attempt is made to provide an integrated view of strategic CSR on projects. A stronger focus will be given to strategic CSR in the context of developing countries. Introduction Before we consider strategic corporate social responsibility, let’s...

The Elusive Project Sponsor

All projects are risky ventures: the larger and more complex the project, the higher the risk of an unsuccessful outcome. The project sponsor is the primary risk taker and owner of the project’s business case. In this article, we consider several scenarios for the...